Heat Exchangers for Drying Chambers: Efficient Solutions from KPTS - Kyivpromtekhservis

Drying chambers are an essential part of many industrial processes – from agriculture and woodworking to food production and energy. The main task of this equipment is to quickly and evenly remove moisture from materials (grain, wood, fruits, vegetables, etc.), ensuring product quality and minimizing energy consumption.

The key role in this process is played by heat exchangers (air heaters) for drying chambers, which provide a stable temperature regime and proper air circulation.

Why are heat exchangers important for drying chambers?

Properly designed and installed heat exchangers allow you to:

- ensure even heat distribution throughout the chamber;

- eliminate “dead zones” where materials may overdry or remain moist;

- reduce gas or electricity consumption;

- improve production efficiency and product quality.

That’s why air heaters have become the standard and most efficient solution for drying processes.

Construction and Materials

Kyivpromtekhservis manufactures heat exchangers from:

- stainless steel – for durability and corrosion resistance;

- structural steel – for reliable operation under heavy loads.

High-quality materials guarantee excellent thermal conductivity, resistance, and a long service life even in harsh operating conditions.

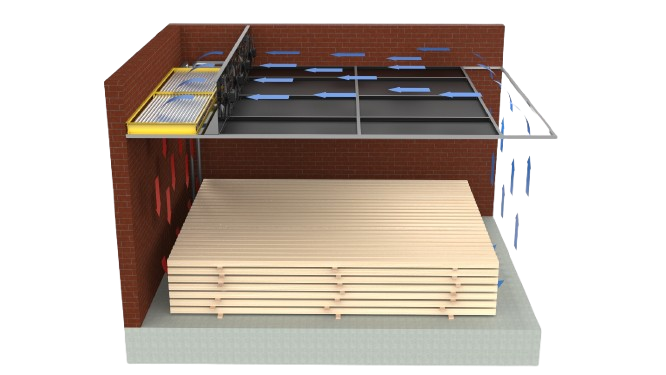

Optimal Installation – the “false ceiling” principle

Our engineers recommend installing heat exchangers in drying chambers along the entire ceiling length. This approach ensures:

- uniform distribution of hot air;

- stable temperature across all zones of the chamber;

- no localized overdrying or underdrying;

- up to 20% energy savings due to optimized airflow.

Practical tips for choosing and operating air heaters

- Heat exchange area. The larger the surface area of the heat exchanger, the more even the heating. Always choose equipment for the specific chamber size.

- Air circulation. Using fans together with heat exchangers ensures maximum drying efficiency.

- Regular cleaning. Dust and deposits reduce heat transfer. Preventive maintenance extends equipment lifetime.

- Temperature control. Automation systems prevent overdrying and excessive energy consumption.

Why choose "Kyivpromtekhservis"?

Since 2002 we have been providing:

- over 20 years of experience in industrial heat exchange;

- production that meets modern ISO standards;

- custom equipment tailored to individual technical requirements;

- a full service cycle – from design to installation and commissioning.

Our clients benefit from reliable equipment, energy efficiency, and cost savings.

Heat exchangers for drying chambers are the key to efficient and cost-effective production. Choosing modern air heaters from Kyivpromtekhservis helps reduce energy costs and increase equipment productivity.

Learn more about our solutions - contact our experts directly.